Timber is a building material derived from wood. Simply put, it is the wood used for construction. It is one of the oldest naturally available materials in use. Three terms associated with timber use are:

- Converted timber: Timber that is sawn and cut into required sizes for commercial use.

- Rough timber: Timber obtained after felling a tree.

- Standing timber: Timber that is in a living form.

RELATED VIDEOS

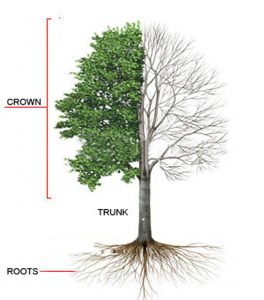

Structure of tree

Basic Structure:

- A tree consists of a trunk, crown and roots.

- Roots anchor the tree to the soil, absorb water and minerals and in turn supply them to the trunk.

- Trunk supports the crown and transports water and nutrients.

Classification of trees:

Depending on the manner in which their stem diameter expands, trees may be described as Endogenous trees and Exogenous varieties.

Exogeneous |

Endogenous |

|

|

|

|

|

|

|

|

- Softwood

- Hardwood

Characteristics |

Softwood |

Hardwood |

| Leaves | Needle-like leaves (conifers) | Broad leaved trees (decidious) |

| Annual ring | Distinct | Indistinct |

| Colour | Light | Dark |

| Density | Low | High |

| Fire resistance | Low | High |

| Weight | Light | Heavy |

| Strength | Weak and can split easily | Strong and durable |

| Examples | Pines, Deodar, Spruces, Fir, etc. | Teak, Sal, Rosewood, Mahogany, etc. |

General uses of timber

Timber is a highly versatile material and its uses are as follows:

1. Construction and Fencing

a) Construction:

- For doors and window frames, shutters of doors and windows, roofing materials, etc.

- For formwork of cement concrete, centring of an arch, scaffoldings, etc.

- For making framework of railway coach wagons.

- For temporary bridges and boat construction.

b) Fencing and Decorating Gardens:

2. Household Uses

a) Utensils:

b) Hand Tools:

3. Art Industry

a) Artworks:

- For artworks such as statues, sculptures, carvings and making decorative objects woods are widely used.

- The frames of art board, color plate are also made from wood in many cases.

b) Musical instrument:

- The musical instruments such as piano, violin, cello, drums, flute, guitar, double bass and a number of other music instruments are made out of wood.

4. Sports Equipment

a) Wooden Appurtenances:

5. Commercial Uses

a) Furniture:

Properties of good quality timber

1. Strength

- The timber should be strong enough to find use as structural members, such as joists, beams, rafters, etc.

- It should able to withstand loads applied gradually or suddenly to it.

2. Hardness

- The timber should be hard enough to resist penetration by another body.

- As such, hardness is imparted to the wood by chemicals present in the heartwood and by the density of wood.

3. Fire-resistance

- As timber is a bad conductor of heat, it should be dense enough to resist fire.

- Good quality timber should not contain resins & other inflammable oils since they accelerate the combustion.

4. Structure

- It should be structurally uniform (homogenous).

- This is ensured when there is firm adhesion of fibres, compact medullary rays and closely spaced annular rings.

5. Elasticity

- This is the ability of a material to retain its original shape after being stretched or compressed.

- Highly elastic timber is useful when it is used for making bows, carriage shafts, etc.

6. Durability

- It should be long lasting.

- It should resist fungal action, insect attack, and chemicals, physical and mechanical agencies during its lifespan.

7. Defects

- It should be free from defects such as shakes, flaws, dead knots or marks.

8. Weight

- Quality timber should possess heavy weight and uniform along is length.

9. Fibres

- Quality timber should possess straight and close fibres, which ensure uniformity.

10. Workability

- Timber should offer ease of workability, meaning it should not clog the saw.

- It should be easily planed.

11. Colour

- Quality timber should process uniform and dark colour.

- Timber possessing low strength is generally light in colour.

12. Sound

- Good timber produces a clear ringing sound when struck.

- Low grade timber produces a dull and heavy sound and indicates signs of decay

Decay of timber

Timber loses its engineering properties due to excessive defects, which can result in decay of wood. Decay of timber may be caused due to:

- Alternate dry & wet conditions.

- Improper removal of sapwood from the wood.

- Formation of fungi, which is responsible for various diseases in wood, viz., dry rot, wet rot, blue stain, sap stain, etc.

- Keeping timber in contact with damp surfaces.

- Improper and incomplete seasoning.

- Non-application of preservatives on the surface of seasoned timber.

- Application of protective coat of paint or tar over unseasoned timber.

- Shocks/impacts received by young timber due to natural forces such as strong winds.

- Improper storage while stacking the timber.

- Exposure to insect attacks such as beetles and termites.

(a) Termites

(b) Beetles

(c) Boarers

Preservation of timber

Timber preservation is required to increase the life of timber, its durability and to prevent damage from fungi, insects, etc.Requirements for a Good Preservative:

- It should be non-inflammable.

- It should not have unpleasant smell.

- It should not be washed away by water.

- It should be capable of penetrating into the fibres.

- It should not corrode the metal pieces attached to the timber

- It should allow other materials such as paints or varnishes to be applied on it.

- It should not get deteriorated by heat, light, etc.

- It should not reduce the strength of timber and warp the structure.

- It should be cheap and easily available in the market.

Types of Preservatives

There are three types of preservatives with different bases as prescribed in the Code (IS: 401:2001).1. Oil Types

- In this type, coal tar creosote with or without admixtures of soluble oils is used.

Oil based presevative

Oil based presevative

2. Organic Solvent Types

- Toxic chemicals in non-aqueous solvents such as copper napthenate, zinc napthenate, benzene hexachloride, etc. are of this type.

Organic Solvent presevative

Organic Solvent presevative

3. Water-base Types

- These are toxic chemicals in water, such as zinc chloride, boric acid, copper chrome arsenic composition, etc.

Water based presevative

Water based presevative

Engineered wood

- Engineered wood is also called composite wood, man-made wood, or manufactured board.

- It forms a range of structural wood products manufactured by bonding together wood strands, fibres, veneers with adhesives or other means of fixing.

Engineered Wood Products

Natural wood can be made into industrial products by certain processes for building construction. These factory made products are also called composite boards. The common industrial timber products are:

Advantages of timber

1. Mechanical Properties:

- Although it is a light material, its strength is quite high.

- It can be used either for load bearing members or for non-load bearingmembers.

- It is generally preferred for the buildings in the earthquake-prone regions.

2. Insulator

- The building with timber construction are found to be cool in summer and warm in winter, as it is non-conductor of heat.

3. Working Properties:

- It can be easily handled and can be planed, sawn and joined.

- The additions, alterations and repairs can be carried out eaily.

4. Versatile material

- As timber comes in many different grades and species, it can be utilized for different needs.

- It can be used for construction as well as commercial purposes.

5. Energy Efficient

- The amount of electricity or its equivalent required for the production of one unit of timber is nearly 6.25 times less than that required for steel and about 40 times less than that required for aluminium.

6. Economical

- The smallest piece of timber can be put to one or other and the wastage of material is thereby considerably minimized.

- It is easily available and can be speedily transported by simple means of communication.

Disadvantages of timber

1. Shrinking and Swelling

- It is a hygroscopic material.

- It has a natural ability to absorb water.

2. Fire Resistance:

- It is highly combustible and requires special treatments.

3. Discolouration:

- Untreated timber which is exposed to the different weather influences it discolours turns to a dark and dirty optic with time.

4. Decay

- It is likely to crack, warp and decay, if not properly seasoned and untreated with preservatives.

5. Maintenance

- It requires regular maintenance.