Tiles are thin slab units for finishing a surface. They are made of brick earth, moulded in suitable sizes and shapes and burnt to a certain temperature.

Note: The best clay for tile making is generally found a few meters below the brick earth.

RELATED VIDEOS

Manufacturing of tiles

General uses of tiles

Tiles can be used not just for covering walls and floors, but also for decoration, protection, landscaping and other uses.

1. Counters

- Tiles are hard and water-resistant, hence they are ideal materials for the moist and humid environment of the kitchen and washrooms.

2. Bathrooms

- Tiles are water-resistant, hence used on floors and walls in bathrooms.

3. Backsplash

- Backsplashes shield the walls against spills from kitchen countertops & sinks.

- Tiles are preferred here because of their natural water resistance.

4. Flooring

- Tiles offer the cheapest flooring choices, being extremely reasonable compared with other materials.

- Tiles for flooring can be installed easily.

5. Wall Panels

- Decorative tiles are used as panels for walls, counters, and flooring.

- They feature a range of patterns and colors.

6. Exterior

- The exterior walls may be faced with tiles mimicing natural materials like wood and stone.

- They are a viable alternative to exterior paints, being more durable and resistant to atmospheric effects.

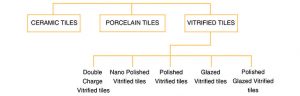

Classification of tiles

1. Ceramic Tile

- 10%-16% water absorption level.

- Ceramic tiles are made up of sand, natural products and clays.

- They are glazed with impervious surfaces.

2. Porcelain Tile

- 3%-7% water absorption level

- Manufacture of these tiles involves subjecting to heavy temperature.

- This process of manufacture allows these tiles to be harder & denser than ceramic tiles.

- These tiles are considered to be better when factors of durability, design, color and value factors are taken into account.

3. Vitrified tiles

- Greater than or equal to 1% water absorption.

- These are made from clay materials mixed with other finely ground materials and are fired at extreme temperatures.

- These tiles have greater abrasion resistance and are used in heavy traffic areas. The hardness of these tiles can be comparable to granite.

- They are polished with carbide or diamond abrasive tools.

a) Double Charge Vitrified Tiles

- These are manufactured by merging 2 layers of tiles.

- This results in the layer becoming 3 to 4 mm thicker.

- This makes it the best choice for heavy traffic commercial spaces.

Advantages:

- DC tiles are long lasting compared to traditional soluble salt tiles

Disadvantages:

- Due to technological limitations, the design patterns are limited.

b) Nano Polished Vitrified Tiles

- Nano polish is derived from Chemical-Nanotechnology.

- It contains functional nano particles that are linked into a silicon matrix in a solvent base.

- Such components form a hidden layer on the surface which has excellent water/dust repellent and anti-bacterial properties.

Advantages:

- Ideal to deal with stains by ink, food items, tea, coffee, liquor, other liquids or dirt.

- Easily cleaned and have anti-bacterial properties.

- Cleaning the surface is simpler and cheaper and therefore, these tiles prove economical.

Disadvantages:

- Initial cost is high.

Note: While choosing Nano tiles, a permanent marker can be used to mark the surface and after few seconds, water should be used to remove the mark. If the stain is removed without much effort, the tiles are authentic nano coated.

c) Polished vitrified tile (soluble salt tile)

- The tile is printed and polished but is not glazed.

- The sheen diminishes in due time.

- Since the tile is not glazed they would contract stains in their pores. To fill in the pores a wax coating is done on the tile nowadays known as nano-coating, but is not deemed as a permanent solution.

d) Glazed Vitrified Tile (GVT)

- A vitrified tile subjected to glazing.

Advantages:

- It offers the option of making customized design and art work.

- Any conceivable design, like marble and wooden patterns is possible.

Disadvantages:

- The digital technology employed increases the cost. We predict that it will come closer to other type of tiles in short time.

e) Polished Glazed Vitrified tile (PGVT)

- A Glazed Vitrified Tiles subjected to polishing.

Third fire process

A liquid metal (Vitrosa) prints motifs on a processed tile and is again fired incurring high costs.

Installation of tile

Laying of tiles

- The tile should first be dipped in water for pores and spread out on a level floor for any inflections or shade variation before application.

Spacers

- 3-4mm spacers along with matching grout colour are advised during tile installation to avoid bending of tiles.

- In India, the high temperature variation & fluctuations cause expansion & contraction in the tiles. Breakage of tiles may result due to lack of air gaps. Hence, provision of spacers with proper grouting is required.

Grouting

- It is the method used to fill the voids in or between the tiles with grout.

- Grout is mortar containing a significant amount of water so that it has the consistency of a viscous liquid, allowing it to be poured in the gap.

1. Unsanded grout:

- It is commonly known as wall grout and finds use in wall tiles which have grout joints less than 1/8' wide

2. Finely sanded grout:

- It is most commonly used for ceramic tiles is used where the joints between floor tiles are 1/8' to 3/8' wide.

- It is composed of Portland cement, sand and other additives, mixed with water.

- It soaks stains, dirt and spilled liquids.

3. Polished marble:

- It should be installed with a grout width less than 1/8' wide.

4. Quarry type grout:

- It is similar to finely sanded grout, but the grade of sand used is coarser.

- It is useful where the joints vary from 1/2' to 3/8'.

- Saltillo tiles generally employ the use of quarry type grout.

5. Epoxy grout:

- This is composed of an epoxy resin and a hardener.

- It is resistant to stains and chemicals and has excellent bonding capacity.

- Countertops, backsplashes and bathrooms require this type of grout.

6. Furan grouts:

- This type of grout have properties similar to epoxy grouts, but find wide application in industrial plants, laboratories, etc.

Precautions during installations

- Tiles should first be laid on a clean floor and checked for size and color.

- The tiles are dipped in water and soaked for around 1-2 hours for pores.

- The tiles are then laid according to the arrow marks (if given), keeping the arrows in one direction. Arrows are mainly available in small sizes.

Cleaning and maintenance

- Lay the tiles only when the remaining construction process is completed or else should be covered duly if laid beforehand.

- The tiles should be cleaned daily.

Tiles: quality problems

1. Scratches on tile surface

This is a critical problem. Tile scratches are more commonly found in glossy, polished tiles.

Reason

- Tiles tend to slide onto each other during the manufacturing process.

- Mishandlesd during the packaging of tiles in cartons.

- Application of a back wash (a solution of calcium carbonate) on the back side of tiles lend the tiles back side a smooth surface to glide over each other.

- Automation machines which lifts the tiles from the centre and puts it at another location helps in avoiding scratches.

2. Bending of tiles:

It is also called warpage or planarityissue.

Reason

- Exposure to uneven firing in the kiln.

- Improper pressure by the press machine.

- Some equipment manufacturers are providing a new technology (DICO Planar - Planarity control) to check bending. The factory needs to enter the range of bending which is acceptable and the planarity machine will mark each tile which goes beyond that limit.

3. Diagonal and size issues:

If the tiles are not diagonally perfect square or perfect rectangles or if their size varies, it is impossible to install a tile precisely.

Reason for sizing issue:

- Improper sizing.

- System Ceramics offers machinery, DICO Liner - Orthogonal control, which can also control this problem.

Available sizes,thickness and finishes of tiles

Sizes:

| Wall tiles (l x b) | Floor tiles (l x b) | Wooden tiles (l x b) |

|---|---|---|

| 4x4 | 12x12 | 2x2 |

| 8x12 | 16x16 | 16x16 |

| 10x13 | 18x18 | 4x4 |

| 10x15 | 24x24 | 6x24 |

| 12x18 | 32x32 | 8x24 |

| 12x18 | 24x48 | 8x48 |

| 12x36 | 32x48 | 8x96 |

| 18x36 | 32x64 | |

| 16x32 | 32x96 | |

| 48x96 | ||

| 48x48 | ||

| 36x72 | ||

| (All dimensions are in inches) | ||

Thickness:

Normal tiles |

Heavy duty/ Parking tiles |

| 3mm | 14mm |

| 6mm | 16mm |

| 7mm | 18mm |

| 9mm | 20mm |

| 10mm | |

| 12mm | |

| 13mm |

Finishes:

Glossy (interior):

- Tiles have a shiny reflective surface coating and are easy to clean.

Matte Finish:

- These tiles have a granular and hard surface with a non-reflective finish.

- These tiles are slip-resistant and dull in appearance.

Satin Finish:

- A smooth surface that has a subtly reflective sheen.

- Its finish is somewhere between glossy and matte finish.

Rustic Finish:

- This finish has a rough-hewn or roughened surface.

Lappato Finish:

- This is a form of tile that has been polished but not deep enough to attain the lustre of a full reflective polish.

- The surface finish has an uneven nature.

Textured Finish:

- A surface with a tactile finish.

Sugar Finish:

- This surface has a granular touch. It is comparatively harder to clean.

Advantages of tiles

1. Variety

- Tiles offer design flexibility as they can be customized and moulded easily compared to stones.

2. Corrosion and scratch resistant

- They are highly resistant.

- Tiles regulate building heat and bring down building temperatures by several degrees.

4. Easy to use

- Tiles can be glued easily over an already existing material.

5. Eco-friendly

- Most of the tiles are eco-friendly as they cause no harm to nature in manufacturing.

6. Durable

- Tiles are durable and they have a long life.

Disadvantages of tiles

1. Bending

- Tiles are vulnerable to bending.

- Temperature fluctuations during the firing process may result in bending.

2. Cracking and chipping

- This can happen depending on the quality of installation and whether a proper subfloor has been installed.

3. Difficult to repair

- It is nearly impossible to repair a tile once defected.

4. Tile grout life

- While tile can last for a lifetime, tile grout can discolor and is hard to maintain.