Laminate is a thin decorative surface layer that is usually glued on a substrate to create a countertop.

RELATED VIDEOS

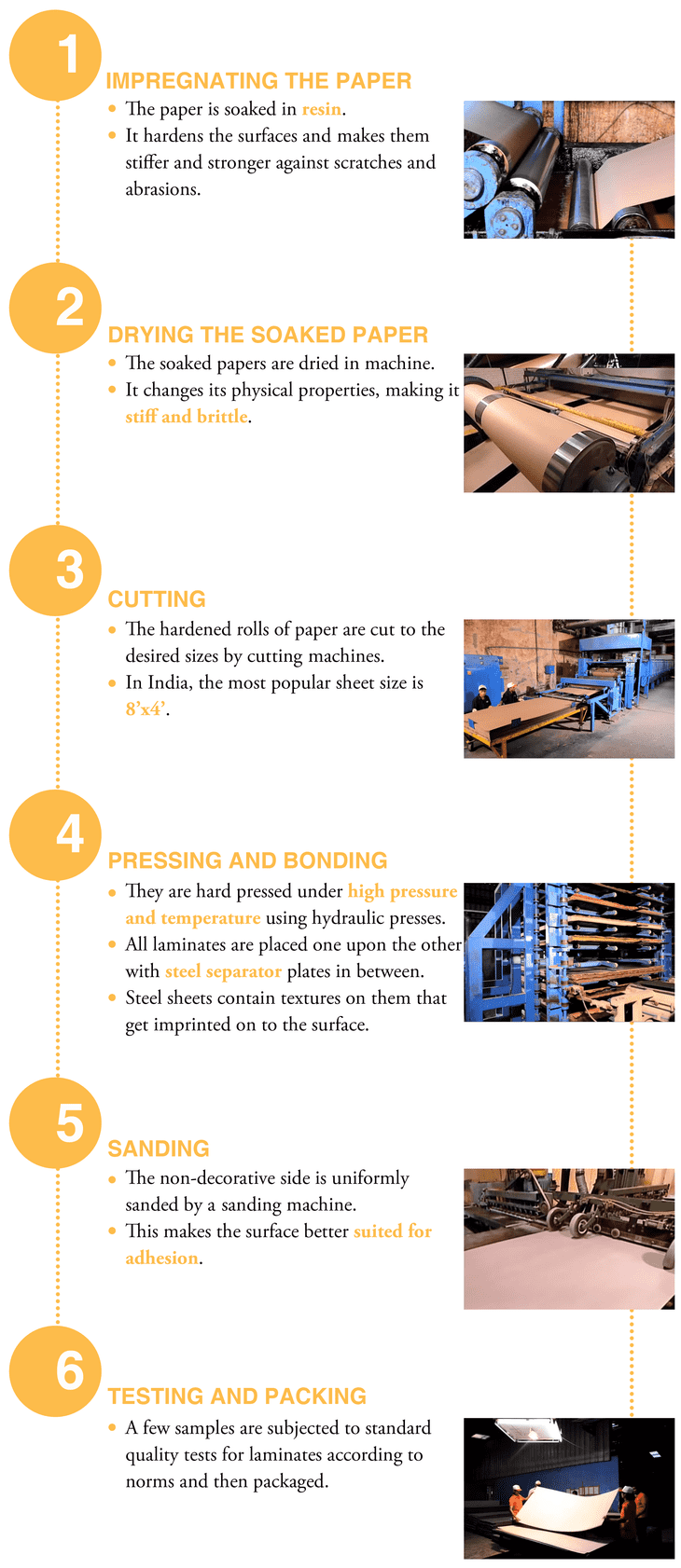

Manufacturing of laminates

Note: The thickness of laminate sheets ranges from 0.6 mm to 1.5 mm, and more layers of paper can be used according to requirement. Much thicker laminate sheets (3mm to 30mm thickness) are also manufactured and these are known as compact laminated sheets. They are stiff and self-supporting. Such compact sheets can be used independently without the need to glue them onto plywood, particle board, MDF or any other base materials.

Types of laminates

a. According to Pressure Applied

1. High Pressure Laminates (HPL)

- These laminates are manufactured by attaching decor paper to kraft paper at high pressure.

- These comprise hard decorative panels that possess high durability and strength.

- They are attached to plywood and MDF for making furniture.

2. Low Pressure Laminates (LPL)

- These laminates employ the use of decorative sheets soaked in melamine resin.

- The laminated paper is then directly bonded to Particle boards of fibre boards (MDF and HDF).

b. According to Thickness

1. Regular Laminate Sheets

- The thickness of regular laminate sheets ranges from 0.6 mm to 1.5 mm.

- These sheets are glued to a substrate materials such as plywood.

2. Compact Laminate Sheets

- Their range of thickness is 3mm-30mm.

- Compact laminate sheets are self-supporting, water resistant and highly durable laminates.

c. According to Usage

1. Decorative Laminates

- These are laminated products primarily used as furniture surface materials or wall paneling.

- Sheets are manufactured in wide variety of colours, patterns and textures.

2. Industrial Laminates

- These laminates possess high resistance to scratches and abrasions.

- They are more durable for industrial applications. They are adopted for use in office furniture, circuit boards, etc.

d. According to Surface Finish

1. Solid Colored Laminates

- These laminates feature a single solid colour.

- They find use in bathrooms and kitchen countertops.

2. Gloss Finish Laminate

- These laminates feature a lustrous finish, and are used to enhance the appearance of furniture.

- Restaurants and hotels mostly use gloss finished laminates.

- They can be used in kitchens and living area for easy cleaning.

3. Matt Finish Laminates

- These laminates are used to add a smooth and subtle finish, without any shine.

- The effect is generally seen as part of corporate office furniture.

4. Textured Laminates

- They possess surface patterns or textures, that one can touch and feel.

- They imitate the textures of real wood, stone, leather or other materials.

- They are used in wall and floor finishes.

5. Wood Grain Laminates

- Wood grain laminates are designed to resemble natural wood.

- They are widely used to laminate wooden flooring.

6. Metal Laminates

- Metal laminates impart metallic effect to furniture.

- They are used in commercial shops and showrooms.

7. Leather Laminate Sheets

- Leather laminate sheets resemble original leather.

- They are used in cabinets and other furniture and d?cor elements.

8. Digital Laminate Sheets

- These are custom-made printed laminates to fulfill interior requirements.

- These sheets offer ample scope for artistic expression.

e. According to Advanced Properties

1. Fire Rated Laminate

- Special fire resistant resin is used in the manufacture of these laminate.

- They are used for interior decoration in fire prone applications in industries, airports, hospitals, institutions, banks, kitchens, etc.

2. Anti-Bacterial Laminate

- These laminates have anti-bacterial properties.

- These laminates are preferred in hospitals and restaurants to ensure high hygiene levels.

3. Electrostatic Dissipative Laminate

- These laminates provide protection to electronic and other static-sensitive devices from electric charges that could damage them.

- These laminates are used for manufacturing circuit boards, and in hospitals, laboratories, etc.

4. Magnetic Laminate

- These laminates possess strong magnetic effects.

- These laminates can find use in offices and hospitals for holding reports, notice boards etc. and in houses holding photographs and schedules.

5. Marker or chalk board Laminate

- These laminates possess a non porous, lustrous surface which makes it suitable for marker pens for writing and wiping.

- These laminates have extra thickness with abrasion resistant characteristics.

f. According to Built

1 Unicore Laminates

- These laminates possess identical surface and core colours, creating a neat and uniform appearance. They are used to cover home furniture, counter tops, shelves, etc.

2 Noncore laminates

- In these type of laminates, the edge of the surface is generally black i.e. wood.

- These laminates are economical than Unicore laminates.

Different laminates and their application area

Types of Laminates |

Preferred areas |

| Matt Finish Laminate | Business and corporate environments, living rooms, bedrooms etc. for subtle and stylish appearance. |

| Gloss Finish Laminate | Clubs, industry events, showrooms, shops, kitchens etc. It adds lustre to furniture and is also easily cleaned. |

| Metallic Finish Laminate | Commercial spaces and showrooms. |

| Textured Finish Laminate | Living rooms, decorative elements, business and corporate environments etc. for subtle and classy look. |

| Solid Color Laminate | Kitchen counter taps, bathroom areas, bedrooms etc. |

| Unicore Laminate | Kitchens, bedrooms, commercials and water prone areas. |

Advantages of laminate

1. Eco friendly

- Laminates offer endless recycling possibilities.

- It is partially made of recycled content.

2. Economical

- It is more economical and easy to install.

3. Customizable

- It offers hundreds of choices as compared to other synthetic materials.

4. Versatility

- Options range from solids to customized ones resembling a variety of textures such as stone, wood, leather, etc.

- Laminate design is subject to endless possibilities.

5. Durability

- It is highly durable, hygienic and quite easy to maintain.

6. Seamless

- Laminates are highly scratch and abrasion resistant.

7. Safety

- They have anti-bacterial properties.

- They are moisture impact and shock resistant.

8. Maintenance

- Laminates can be easily cleaned.

- Laminates do not require painting or polishing.

9. Installation

- It can be installed over almost any existing floor.

- It is easier to install than many traditional surfaces.

Disadvantages of laminate

1. Relatively poor quality

- Veneers offer better quality and richer texture than laminates.

2. Toxic

- Laminates are considered to be slightly toxic, as they release certain volatile organic compounds, including formaldehyde.

3. Prone to abrasion

- The whole floor may need replacement if the laminate wears out.

- Laminates are brittle in nature and get chipped easily.

4. Unsafe

- Laminate flooring may be slippery and compromise safety.