The glass is a mixture of a number of metallic silicates, one of which is usually that of an alkali metal. It may also be considered as a solidified super-cooled solution of various metallic silicates having infinite viscosity.

In modern architecture, glass is an essential material as it provides flexibility and aesthetics to the structure. It is a versatile material to work with in the design perspective. It adds vibrancy to the building and bridges the interior to the outside.

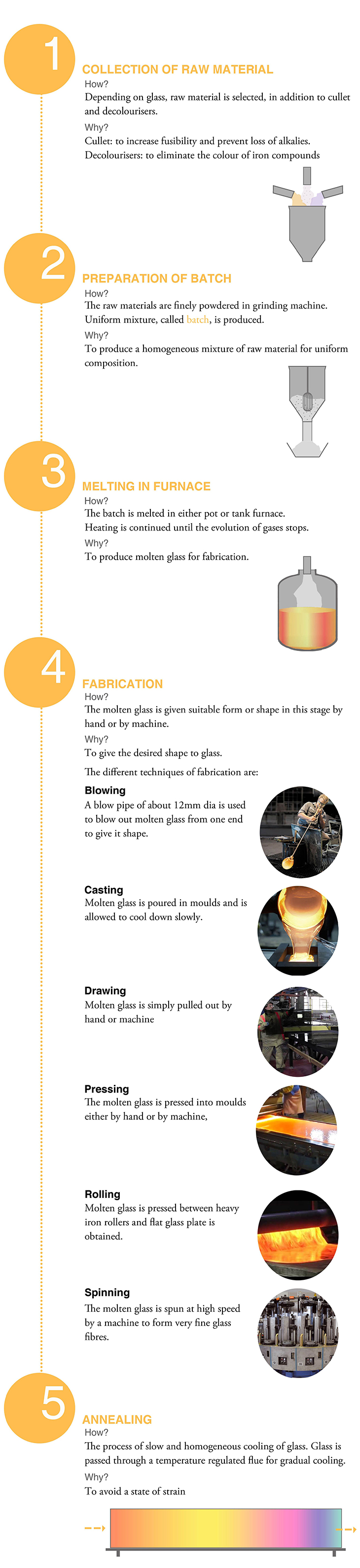

Manufacturing of Glass

Manufacturing of glass involves the following processes:

Properties of Glass

- It is transparent, translucent and a good insulator.

- It absorbs, refract and transmit light.

- It can take up high polish and become a substitute for costly gems.

- It has no definite crystalline structure.

- It has no sharp melting point.

- It is affected by alkalis, but it is not easily attacked by ordinary chemical reagents.

- It is an excellent electrical insulator at elevated temperatures.

- It behaves more as a solid than most solids in the sense that it is elastic. But when the elastic limit is exceeded, it fractures instead of deforming.

- It can be worked upon in various ways like blowing, drawing and pressing.

- It is extremely brittle.

- It is possible to alter its properties like fusibility, hardness, refractive power, etc.

- It is possible to weld glass pieces by fusion.

- It is very sustainable as it is recyclable and natural.

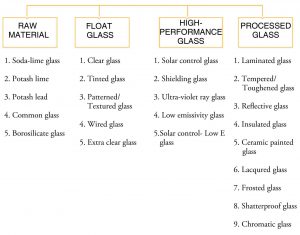

Types of Glass

Based on Raw Material

Types of Float Glass

1. Clear Glass

- The molten glass coming out of furnace is allowed to float on molten tin.

- It is aesthetic in appearance and its use has opened unlimited possibilities in architectural design as it is available in larger sizes and thicknesses.

- It is cost-effective as compared to corresponding cost of brick wall, finishing material, paint, maintenance, etc.

Uses: Artificial stones, window panels, fancy articles, decorative tiles, etc.

2. Tinted glass:

- Colouring pigments are added while preparing the batch for its manufacture.

- Different quantities of same substance can produce different colour to glass.

| Materials (oxide form) | Colour produced |

|---|---|

| Iron | Green, Brown, Blue |

| Chromium | Green, Yellow, Pink |

| Cobalt | Blue, Green, Pink |

| Copper | Blue, Red, Green |

| Nickel | Yellow, Purple |

| Manganese | Purple |

| Carbon, Sulphor | Brown, Amber |

| Calcium phosphorite , tin | White-opaque |

Uses: Artificial stones, window panels, fancy articles, decorative tiles, etc.

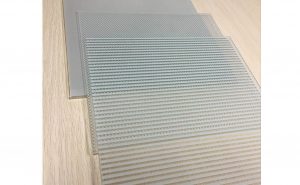

3. Patterned / Textured glass:

- This glass has one surface either ground or made opaque by melting powdered glass upon the surface.

- The several types include figured glass, ground glass, chipped glass and corrugated glass.

Uses: Where vision is to be blocked but light is needed like public toilets, office doors, partitions, etc.

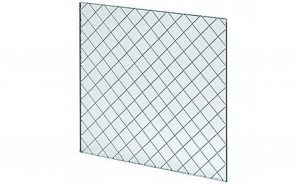

4. Wired glass:

- Steel wire mesh is placed in glass during rolling operation. The mesh may have hexagonal or square units.

- If glass breaks, pieces of glass are held by wire in position.

- It is also fire-resistant.

Uses: Roofs, skylight, fire-resisting doors and windows, etc.

5. Extra clean glass:

- This glass is a high quality glass which is free from impurities such as iron.

Uses: Making tabletops, in the showroom of jewelry items, watches, crystal ware items, fine fabrics and art wares item, etc. for a sparkling display.

Types of High Performance Glass

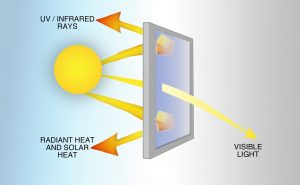

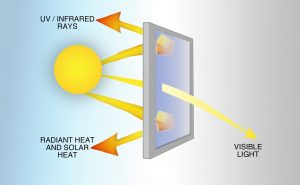

1. Solar Control Glass

- This glass is a hi-tech special oxide coated glass product that allows sunlight to pass through it while radiating and reflecting away a large degree of the sun's heat.

- For tropical countries like India, this type of glass is very suitable as it helps in reducing the amount of air-conditioning required.

Uses: Skyscrapers as glass facades in modern buildings, conservatory roofs, air conditioned malls and showrooms, etc.

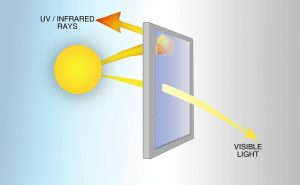

2. Low emissivity glass:

- This glass has excellent thermal insulation properties. It allows only visible light to enter the room and thus gives protection from UV and infrared rays.

- In cold climates, they help in maintaining the temperature of interior, and provide energy efficient solution.

Uses: Glass facades, roofs, skylights, and fenestrations.

3. Solar control-Low emissivity glass:

- For facades, which are in direct contact of sunlight, only low E glass cannot be used, as they tend to trap the heat inside, which leads to overheating of interiors.

- In such case, solar control low E glass is used, which blocks solar radiation, as well as provides thermal insulation.

Uses: Glass facades, roofs, skylights, and fenestrations.

Types of Processed Glass

1. Laminated Glass

- It is made by sandwiching a layer of polyvinyl butyl between two or more layers of glass.

- It includes the following types:

1.1 Bullet-proof glass:

- The glass is made of several layers of plate glass and alternate layer consists of vinyl- resin plastic.

- The thickness of this glass vary from 15mm-75mm or more.

Uses: Windows of buildings that require security, such as jewellery stores, embassies, as well as military and private vehicles.

1.2 Heat-proof glass:

- The glass is made of several layers of plate glass and alternate layer consists of vinyl- resin plastic.

- The thickness of this glass vary from 15mm-75mm or more.

Uses: Windows of buildings that require security, such as jewellery stores, embassies, as well as military and private vehicles.

1.3 Sound-proof glass:

- This glass is usually thin, but is used to block sound through it.

- For areas where high noise is produced, double or triple glazed untis of glass are used.

Uses: Offices, music recording studios, meditation rooms, conference hall, interrogation rooms, internet broadcasting space, etc.

1.4 Safety/ Shatterproof glass:

- This glass is formed by placing celluloid between two sheets of plate glass and applying glue to make it a single unit.

- If it breaks, there are no flying splinters.

Uses: Facades, doors furniture, partitions, windscreens, etc.

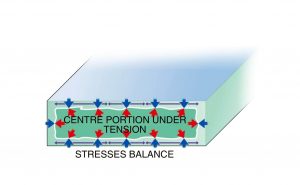

2. Toughened / Tempered glass:

- It is a strong glass which is heated to a uniform temperature and rapidly cooled to increase the strength.

- It is stronger than other glasses of equivalent thickness.

Uses: Escalator side panels, handrails, balustrades, staircase handrails and viewing partitions of sports complexes, resorts, and airports

3. Heat treated glass:

- It is processed with heat treatment for durability and safety reasons.

- Its mechanical strength is twice that of normal annealed glass and half of fully tempered glass.

Uses: Structural glazing as they safeguard against thermal breakages.

4. Reflective glass:

- It imparts a mirror like an appearance and wide palettes of colours to the exterior of buildings during daytime.

- Metal oxide coating is applied to one side of the clear or body tinted glass in order to increase the amount of reflection by the glass.

Uses: Office and high rise building doors, windows and glazing for privacy.

Uses: Office and high rise building doors, windows and glazing for privacy.5. Insulated glass:

- These are prefabricated units made of two or more glass panes which are separated by cavities filled with dry air.

- They provide excellent thermal and sound insulation properties.

Uses: Office buildings, hospitals, hotels, houses, buildings with high heating or cooling requirements or that need the temperature and humidity controlled

6. Lacquered glass:

- Coloured and opaque in appearance, it is produced by depositing and then baking a coating of lacquer to one side of clear glass.

- Lacquer is a solution of film-forming materials, natural or synthetic, usually applied as an ornamental or protective coating.

- It brings colour and ambiance to interiors with a durable.

Uses: In interiors in bathrooms and kitchens, offices, hotels, shops and museums, as wall-panelling, in furniture and in wardrobe and cupboard doors.

7. Ceramic printed/ Silk screen glass:

- This glass is typically formed from lithium alumino silicate glass, and is extremely resistant to thermal shock.

- This glass is used when it is important to mask a part or whole of glass for privacy or hiding the background.

Uses: Curtain walls, shower installations, glass doors, spandrels, and partitions, stair rails, conference room, etc.

8. Fibre glass:

- This glass is composed of minute glass rods and each glass rod resembles the parent material in all respects.

- It does not absorb water and it is proof against fire, vermin, water and acids.

Uses: Thermal insulations, sheets, fibre glass reinforced plastics, etc. From roof insulation to medical equipment it has various uses.

9. Frosted glass:

- It is produced by the sandblasting or acid etching of clear sheet glass.

- This creates a pitted surface on one side of the glass pane and has the effect of rendering the glass translucent, thus blurring images while still transmitting light.

Uses: Shower cubicles, conference rooms, office partitions, windows and doors of bedrooms, dressing rooms, etc.

10. Chromatic glass:

- It may be photochromic which has light sensitive lamination, thermos-chromatic which has heat sensitive lamination and electrochromic which has electric lamination over it.

- It can control the transparent efficiency of glass and protects the interior from daylight.

Uses: Intensive care units, meeting rooms, etc.

Glass Products used in Construction Industry

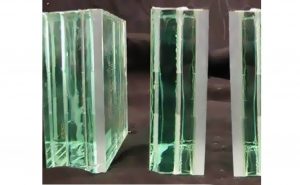

1. Glass Blocks:

- These are partially evacuated and completely sealed hollow units which are formed by fusing together, two-halves of pressed glass.

- The edges are coated with a grit bearing plastic material to ensure effective bond with mortar.

- They are available in square sizes with dimensions 150mm, 200mm and 300mm with thickness 100mm.

Uses: Partition walls or screen walls across part of a room, around a shower or bath, as part of stair constructions, etc.

2. Glass foam:

- It is a cellular glass insulation material which is impervious to moisture, inert, resistant to insects and vermin, strong, and well-insulating.

- It is made my mixing fine ground glass and carbon.

- It is available in form of rectangular blocks.

Uses: Insulating roofs, walls, and below-grade applications, including beneath slabs.

3. Glass wool:

- It is an insulating material made from fibres of glass arranged using a binder into a texture similar to wool.

- The process traps many small pockets of air between the glass, and these small air pockets result in high thermal insulation properties.

- It is produced in rolls or in slabs

Uses: Insulation in roofs, wall, etc.

Treatment on Glass

1. Bending:

- Glass in form of rods, sheets or tubes is placed in temperature-regulated oven. It is then bent when suitably heated.

2. Silvering:

- A very thin coat of tin is applied on the glass. Silver is deposited on this layer of tin.

- A suitable paint is then applied to give protection.

3. Cutting:

- The glass is cut in required size with the help of diamond, rough glasses or hardened steel wheel.

4. Opaque making:

- It is done by grinding the surface with emery.

- It can also be achieved by application of hydrofluoric acid.

Advantages of Glass

- It is a very light weight building material hence helps in reducing dead load of the building.

- It offers unobstructed views thus making the interiors look big. When used in the exteriors it helps in bringing the outdoors into the indoors.

- When used as curtain walling in the facade the interiors are flooded with natural light.

- The external glass can be treated so as to reduce glare, prevent heat absorption and resistance to UV light. This helps in making the building energy efficient.

- The glass is fully weather resistant so it can withstand the effects of the wind, rain, or the sun and can retain its appearance and integrity.

- It does not rust so it does not degrade gradually by chemical and surrounding environment effects.

- Available in varieties of colours and textures.

- Glass is 100% recyclable without loss of quality or purity and it does not degrade during the recycling process.

Disadvantages of Glass

- It is a very costly material and has to be handled with care.

- It requires regular cleaning. In high rises, external cleaning and maintenance can be very challenging.

- Manufacturing of glass is high energy consuming process due to high temperature required for processing the raw materials.

- The glass is very rigid and brittle material so when it is subjected to stress, it breaks. Broken pieces of glass may be sharp and can cause injury.

- The glass is less impact resistant so the capability of the glass to withstand a suddenly applied load is very poor.

- It is affected by alkali ions. They simply dissolves a glass surface.

- Use of glass also enhances the cost of security.

- It absorbs heat and hence act as a greenhouse and hence not suitable in warm and hot climates. It will increase AC load and more energy consideration for air conditioning.