Presence of moisture or standing water can cause damage to the structure of building and health of people living in it. Measures to mitigate the causes of dampness at the time to designing and construction can prolong a building's life.

DAMPNESS

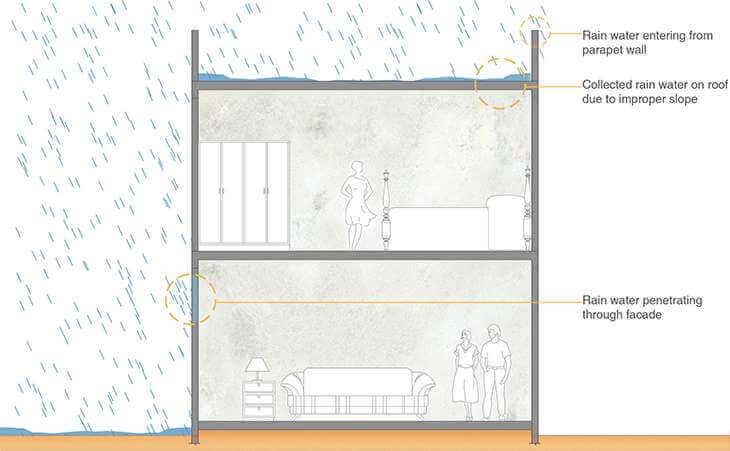

Structural dampness is the presence of unwanted moisture in the structure of a building, either the result of intrusion from outside or condensation from within the structure.

Such dampness is a big threat to building as it has severe effects on the structure of building, furniture, hygiene, as well as the health of the occupants.

Causes of Dampness

1. Capillary Action of Ground Water

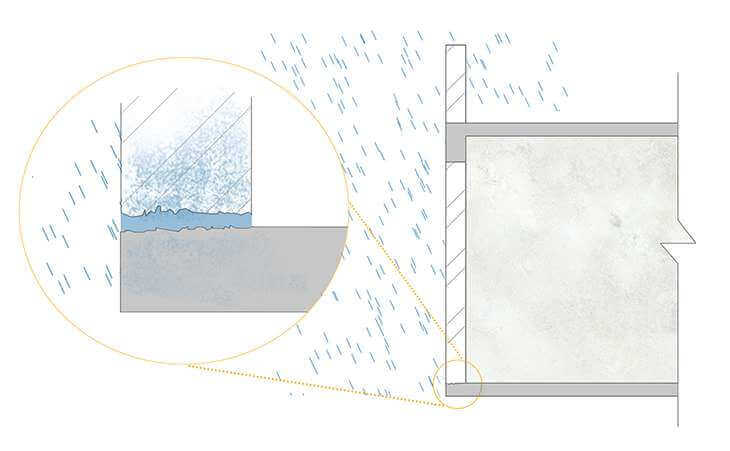

2. Rain Water Penetration

Dampness rising in a wall junction

Dampness rising in a wall junction

3. Improper Plumbing Conditions

4. Low Quality or Defective Construction

5. Moisture entrapped during Construction

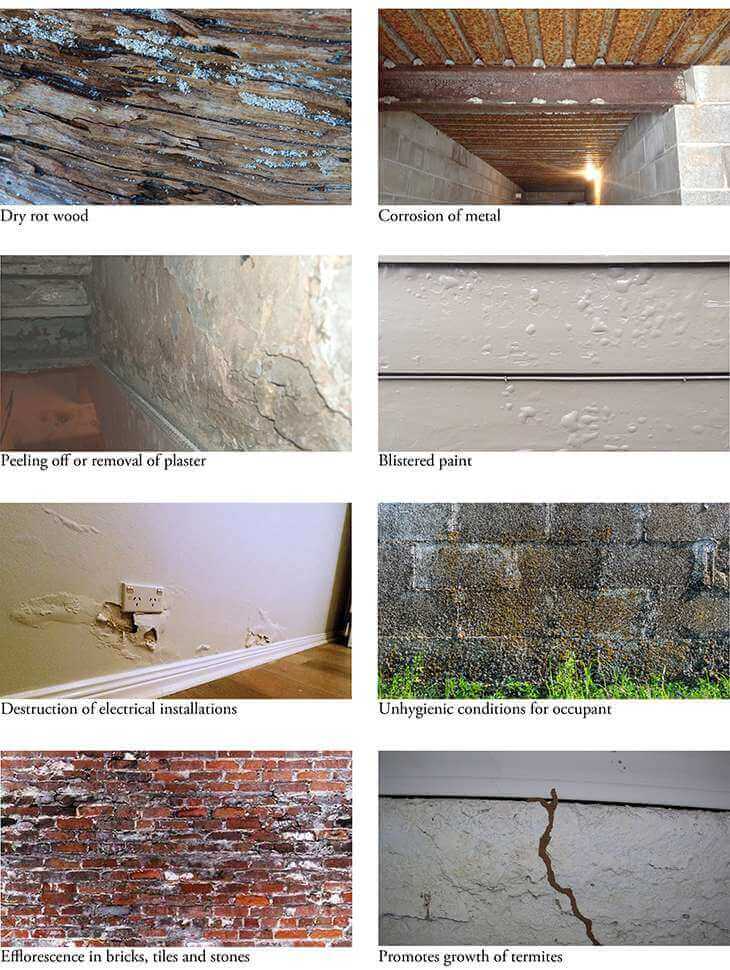

Effects of Dampness

Dampness has several effects on the structure like providing bad musty smell from the structure and reducing its life. Some of them are shown below:

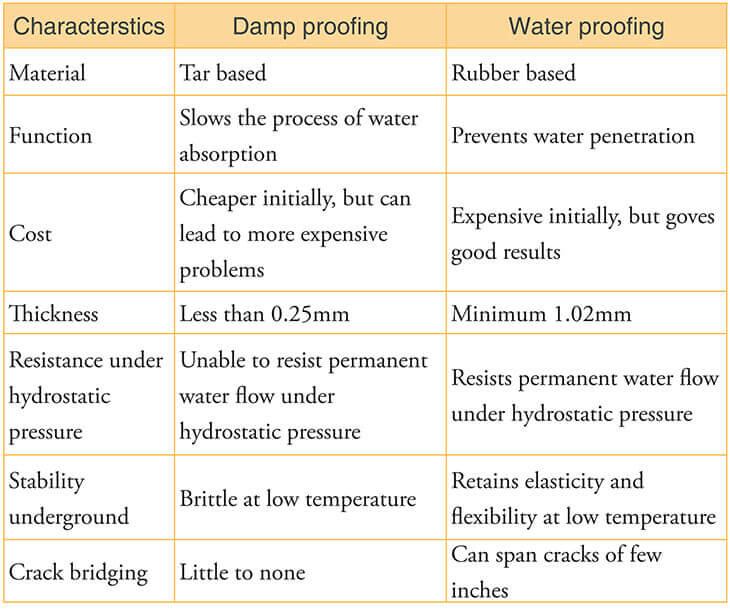

Damp Proofing

Damp proofing is a general term that covers methods and treatments used to prevent dampness from being absorbed through walls or floors into the interior of a property.Water Proofing

Waterproofing in buildings is the formation of an impervious barrier over surfaces of foundations, roofs, walls and other structural members of building to prevent water penetrations through these surfaces. It is generally required for basement of structure, walls, bathrooms and kitchen, balconies, decks, terrace or roofs, green roofs, water tanks, swimming pools etc. Note: The primary variables to consider when determining whether to use damp proofing or water proofing for your structure include: soil conditions, water table level, local drainage conditions, sub-grade depth and the degree of moisture tolerable for the interior of the structure being provided water protection.Damp Proofing vs Water Proofing

Qualities of Good Material

- Impervious

- Durable (ideal for entire building life)

- Steady

- Load resistant

- Flexible

- Dimensionally stable

- Cheap

- Salt free

Materials used in Damp Proofing and Water Proofing

1. Bitumen

Material

- Black viscous mixture of hydrocarbons obtained naturally or as a residue from petroleum distillation.

Application

- 3mm layer of bitumen is applied over bedding of concrete or mortar.

- It is applied with brush in hot condition.

2. Bituminous or asphaltic felt

Material

- Rolled flexible material made of bitumen used in parapet walls, roof, etc.

Application

- It is provided with an overlap distance of 100mm on sides. These laps are then sealed with bitumen.

- Application of asphaltic felt on roof.

3. Mastic asphalt

Material

- Composed of suitably graded limestone aggregates bound together with asphalt cement.

Application

- It is carefully spread when hot by means of a hand float.

Application of mastic asphalt on roof

Application of mastic asphalt on roof

4. Bricks

Material

- Bricks with water absorption of less than 5% are used for this purpose.

Application

- 2-5 courses of such bricks are laid with cement mortar.

5. Stones

Material

- Granite, trap and slates are used.

Application

- These stones are used to full width of wall.

Stone laid as damp proof course to the full width of wall

Stone laid as damp proof course to the full width of wall

6. Mortar

Material

- Cement mortar with 1:3 ratio and ample amount of lime and waterproofing agents is used.

Application

- It is laid in foundation, ground slab, parapet wall, plaster, external wall.

7. Concrete

Material

- Rich concrete mix with ratio 1: 1.5 : 3 or 1: 2: 4 with thickness of 75mm to 100mm.

Application

- Concrete painted with two coats of hot bitumen is used as horizontal D.P.C.

Cement mortar with waterproofing agents used in wall

Cement mortar with waterproofing agents used in wall

8. Metal sheets

Material

- Copper, aluminium, lead are used for construction joints.

Application

- Sheets of metal should be coated with asphalt and laid in full thickness of wall.

- Bituminous seal must be provided for this type of waterproofing.

9. Plastic sheets

Material

- Black polythene sheets of thickness 1mm.

Application

- Sheets are spread and lapped 150 mm at joints and continued across surrounding walls, under the dpc for the thickness of the wall.

Note: It depends upon the climate and atmospheric conditions, nature of structure and the situation where DPC is to be provided.

Note: It depends upon the climate and atmospheric conditions, nature of structure and the situation where DPC is to be provided.

Methods of Damp Proofing

- Membrane damp proofing

- Surface treatment

- Integral damp proofing treatment

- Cavity walls construction

- Guniting

- Pressure grouting

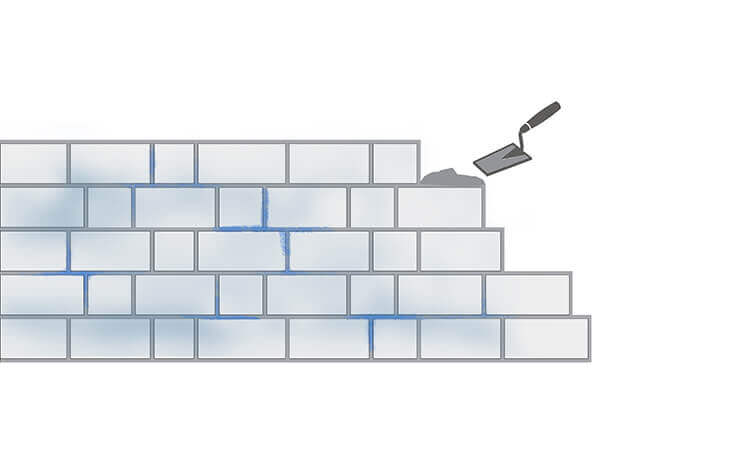

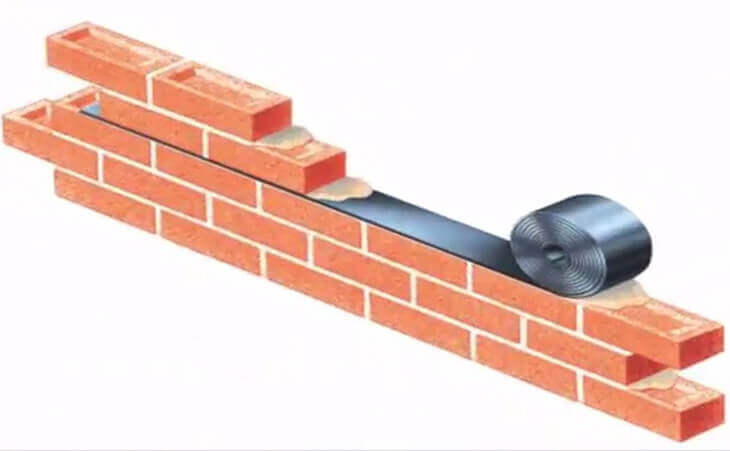

1. Membrane Damp Proofing

- Water repellent membrane is provided between the source of dampness and the part of building adjacent to it.

- It may be provided horizontally or vertically

- It should cover full thickness of wall.

Layer of DPC in brick wall

Layer of DPC in brick wall

2. Surface Treatment

- Application of layer of water repellent substances on surface through which moisture can enter.

- Painting and plastering of exposed surfaces is done using water proofing agents like sodium or potassium silicates, aluminium or zinc sulfates, barium hydroxide and magnesium sulfate.

3. Integral damp proofing treatment

- It consists of adding certain water proofing compounds of materials to the concrete mix to make it impermeable.

| Compound | Action |

| chalk, talk, fullers earth | fill the voids of concrete under mechanical action principle |

| alkaline silicates, aluminium sulphate, calcium chlorides | reacts chemically with concrete to produce water proof concrete |

| soap, petroleum, oils, fatty acid compounds like stearates of calcium, sodium, ammonia, etc. | makes concrete water repellent |

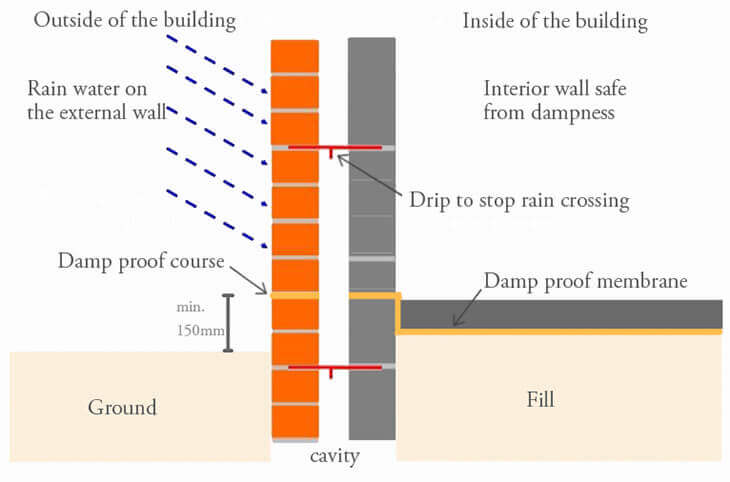

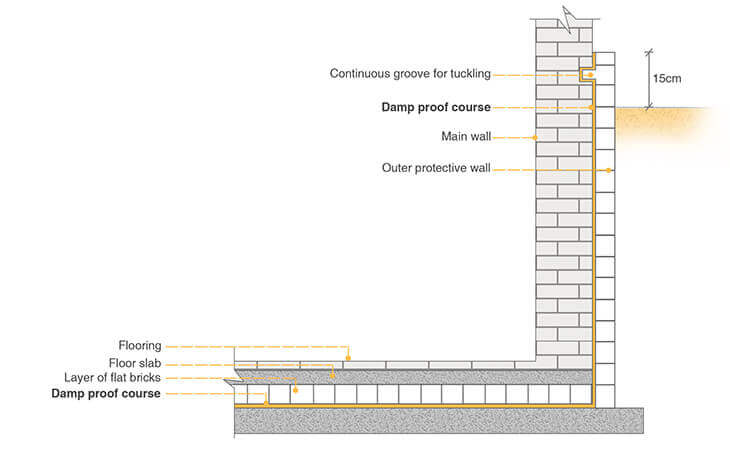

4. Cavity wall construction

- Main wall is shielded by an outer skin wall, leaving a cavity between the two.

- The purpose of the cavity is to act as a barrier to the penetration of rain water to the inside of buildings.

- D.P.C. and membrane is provided below floor level in both the walls.

5. Guniting

- Layer of rich cement mortar is deposited by pressure to the exposed surface of walls, pipes etc.

- It is shot on clean surface with cement gun under 2 - 3kg/cm.sq. pressure.

- The nozzle of machine is kept at a distance about 75 - 90cm from wall.

6. Pressure Grouting

- Cement grout is filled in cracks, voids in the structure by pressure.

- This method controls entry of ground water through foundations.

Cavity wall for damp proofing

Cavity wall for damp proofing

Types of Water Proofing Based on Material

- Cementitious waterproofing

- Liquid waterproofing membrane

- Bituminous coating

- Bituminous membrane

- Polyurethane liquid membrane

1. Cementitious waterproofing

- The materials are easily available from suppliers of masonry products, and are easy to mix and apply.

Uses:

This method is often used in the internal wet areas such as toilets.

Applications:

- Water Treatment Plants

- Sewage Treatment Plants

- Bridges

- Dams

- Railway & Subway Systems

- Marine Cargo Ports & Docks

- River Locks/Channels & Concrete Dykes

- Parking Structures & Lots

- Tunnels

2. Liquid waterproofing membrane

- It is a thin coating which consists of a primer coat and two top coats which are applied by spray, roller, or trowel.

- The liquid cures into a rubbery coating on the wall. The elongation properties of the coating can reach as high as 280%.

- The durability depends on what type of polymer the manufacturer uses for the making it.

3. Bituminous Coating

- Its flexibility and protection against water can be influenced by the polymer grade as well as reinforcement of fibre.

Applications:

- Areas that are beneath screed wet, surfaces such as concrete foundations.

4. Bituminous membrane

- Bituminous waterproofing membrane have two types of membrane:

1. Self-adhesive compounds:

- It has low shelf life as bonding properties of the membrane reduces with time.

- Compounds comprise asphalt, polymers and filler, additionally, certain resins and oils may be added to improve adhesion characteristics.

2. Torch on membrane:

- Exposed membrane often has mineral granular aggregate to withstand the wear and tear of the weathering and for the other types of membrane, contractor need to apply one protective screed to prevent the puncture of the membrane.

Applications:

- Low-sloped roofs due to their proven performance.

5. Polyurethane liquid membrane

- Polyurethane is very sensitive to moisture content present, therefore before application, one has to be very careful evaluating the moisture content of the concrete slab, otherwise peeling or de-bonding of membranes may happen after some time.

- This waterproofing method is expensive.

Applications:

- Flat roof area which is exposed to weathering.

Treatments in Building

Treatment of Foundation against ground water

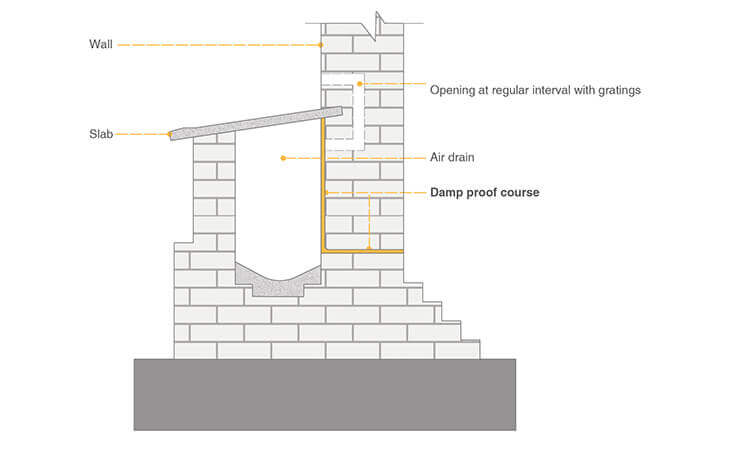

Providing air drain

- Foundation may receive water percolating from adjacent ground. Air drain is provided parallel to external wall to avoid it.

- Openings with gratings are provided at regular interval for passage of air.

- Usual DPC is also provided horizontally and vertically.

Treatment of Basement

Providing foundation drains and DPC

- When basement rests on soil which is not properly drained, hydro static pressure is exerted, hence the floor and wall receive water continuously oozing out.

- Open jointed drains having a suitable longitudinal slope may be provided to collect the underground water.

- Horizontal and vertical D.P.C. are provided in wall as well as foundation concrete.

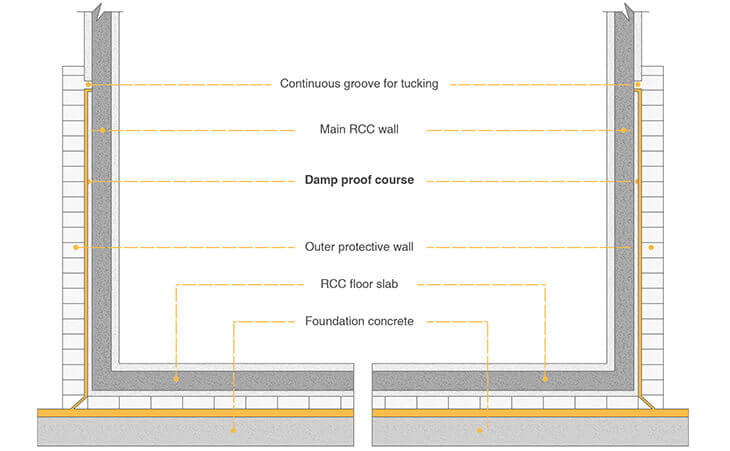

Providing RCC raft and wall slab in damp soil

- When basement rests on soil which is not properly drained, hydro static pressure is exerted, hence the floor and wall receive water continuously oozing out.

- Open jointed drains having a suitable longitudinal slope may be provided to collect the underground water.

- Horizontal and vertical D.P.C. are provided in wall as well as foundation concrete.

Asphalt tanking

- This is adopted when the subsoil water table is not very high.

- The treatment consists of horizontal D.P.C. in the form of asphaltic layer of 30 mm thick in three coats over the entire area of basement floor and then extending it in the form of vertical D.P.C. (asphalt layer of around 20mm) on the external faces of the basement walls.

- The D.P.C. thus functions like a water proof tank on the external faces of the basement, thus keeping it dry.

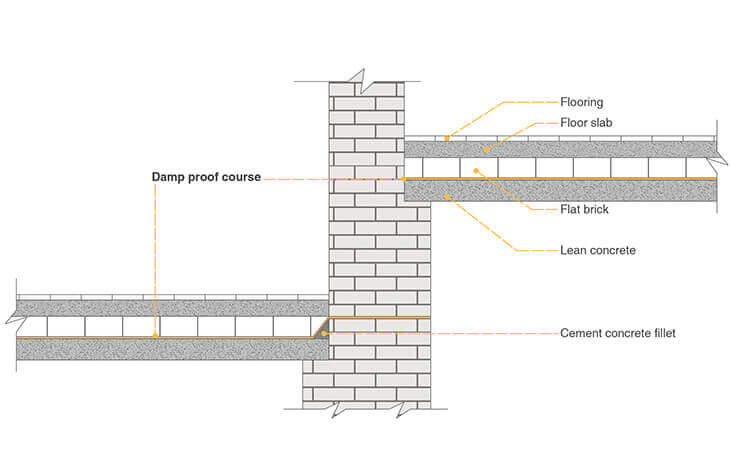

Treatment of Floor

- The choice of material for damp proofing floor is limited to flexible materials which provide lesser number of joints like mastic, asphalt, bitumen felts, plastic sheets etc.

- The felts when used should be properly bonded to the surface with bitumen and laid with joints properly lapped and sealed.

Treatment of wall

Internal walls

- For floors at different heights, the DPC on the internal wall should be at the lower floor.

- It is generally done with water cement slurry plaster. Further this is protected with a protective layer of half brick thick wall.

Section showing damp proofing in internal walls

Section showing damp proofing in internal walls

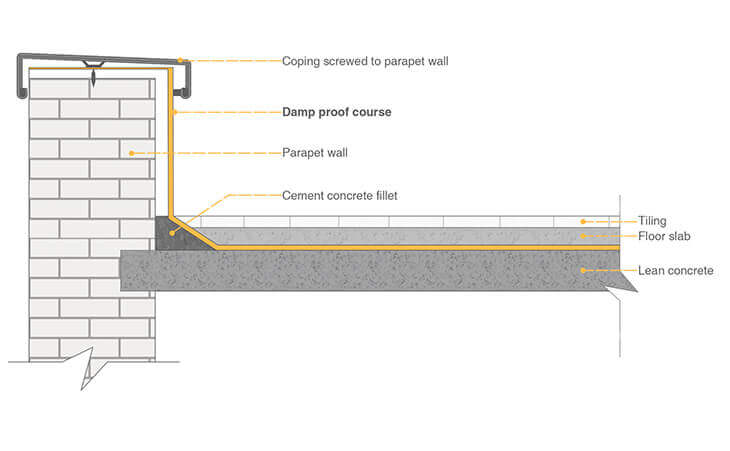

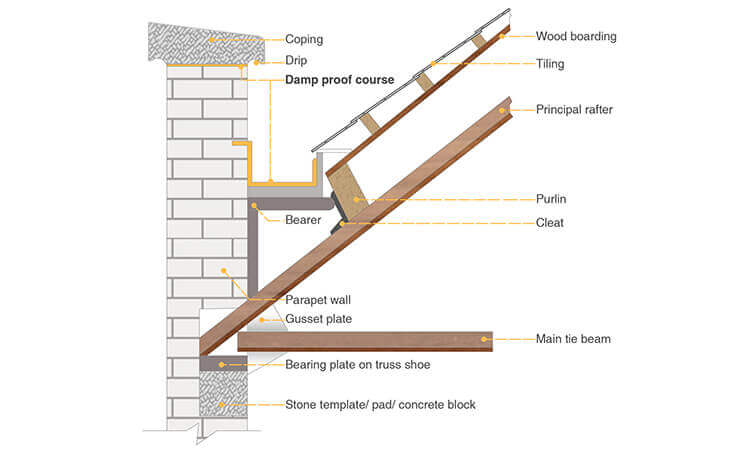

Parapet walls

- Provision of coping on top of the wall surface prevents the entry of damp from the top surface of the wall.

- All forms of coping must be sloped in order to prevent water stagnating on the top surface.

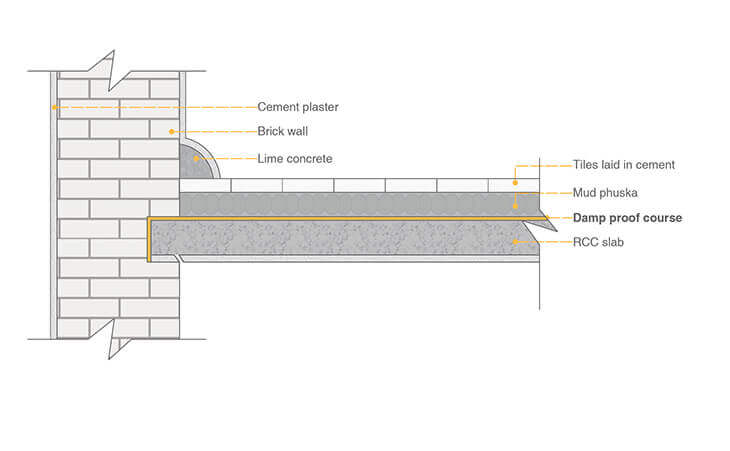

Treatment of roof

Flat roof

- In places, where slopes for the drainage of the roof are given in the roof slab itself, the damp proofing treatment for the roof may consist in laying bitumen felt directly over the surface of roof slab after painting the roof top with hot bitumen.

- Depending upon the type of building, climate and atmospheric conditions of the site, the treatment with felts may be with four courses, six courses or eight courses.

- The four course treatment is recommended for moderate conditions whereas the six and eight course treatment are recommended for severe conditions.

Section showing parapet wall damp proofing

Section showing parapet wall damp proofing

Pitched roof

- Design and construction of roof tiles and roofing sheets must be taken care of. The slope of roof must be sufficient for the particular building.

- Rain water gutters must be of sufficient capacity, water tight and capable of accommodating variations due to temperature changes without leakage.

- Tiles should be projected beyond edge of gutter.

Section showing DPC in pitched roof

Section showing DPC in pitched roof