- Cement, one of the most important building materials, is a binding agent that sets and hardens to adhere to building units and made up of limestone(calcium), sand or clay, bauxite (aluminum) and iron ore, and may include shells, chalk, marl, shale, clay, blast furnace slag or slate.

Function of Cement

- To bind the sand and coarse aggregate together to fill voids in between sand and coarse aggregate particle to form a compact mass.

Composition of Cement

- For understanding cement composition, one must know the functionality of cement ingredients.

- By altering the amount of an ingredient during cement production, one can achieve the desired cement quality.

- There are eight major ingredients of cement. The general percentage of these ingredients in cement is given below:

| Sr.No. | Ingredient | Percentage in cement(%) | Function |

|---|---|---|---|

| 1. | Lime (CaO) | 60-65 |

|

| 2. | Silica(SiO2) | 17-25 |

|

| 3. | Alumina(Al2O3) | 3-8 |

|

| 4. | CalciumSulphate(CaSO4) | 1-3 |

|

| 5. | Ironoxide(Fe2O3) | 0.5-6 |

|

| 6. | Magnesiaoxide(MgO) | 0.1-0.5 |

|

| 7. | SulphurTrioxide(SO3) | 1-3 |

|

| 8. | Alkalis(K2O, Na2O) | 0-1 |

|

Manufacturing of Cement

Stage of Cement Manufacture

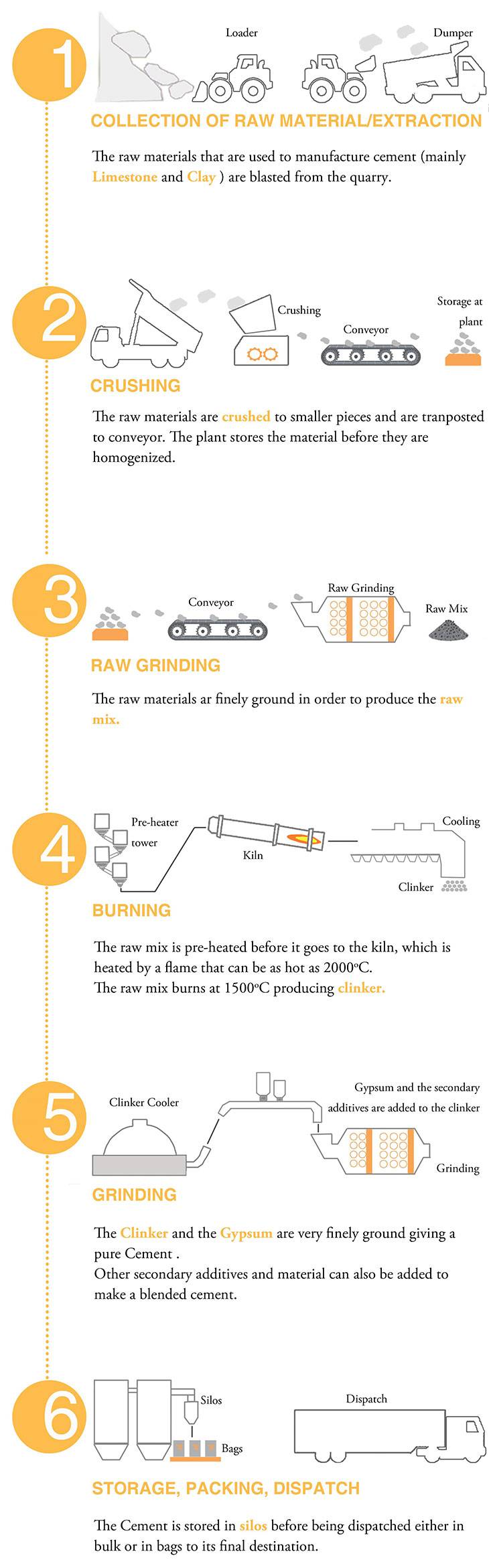

There are six main stages of cement manufacturing process:

Stage 1: Raw Material Extraction/Quarry

- The raw cement ingredients needed for cement production are limestone (calcium), sand, clay, etc.

- The raw materials are blasted from the quarry.

Stage 2: Crushing

- The raw ingredients are quarried and crushed to smaller pieces.

Stage 3: Raw Grinding

- The crushed raw ingredients are then combined them with additives and grinding them to ensure a fine homogenous mixture.

- It can be done through 2 process: a. Dry Process (modern technology) b. Wet Process (old technology)

Stage 4: Burning

- The raw mix is pre-heated before it goes to the kiln, which is heated by a flame that can be as hot as 2000° C.

- The raw mix burns at 1500° C producing Clinker.

Stage 5: Grinding

- The Clinker and the Gypsum are very finely ground giving pure Cement.

- Other secondary additives and material can also be added to make a blended cement.

Stage 6: Storage, Packing and Dispatch

- Cement is conveyed from grinding mills to silos (large storage tanks) where it is packed in 20-40 kg bags.

- Most of the product is shipped in bulk quantities by trucks, trains or ships.

Characteristics of Good Cement

1. The color of cement should be uniformly grey with greenish shade. It gives an indication of excess of lime or clay and the degree of burning.

- 2. It should feel smooth when touched or rubbed in between fingers.

- 3. If hand is inserted in a bag of cement or in a heap of cement, it should feel cool and not warm.

- 4.It should be free from any hard lumps.

- 5. Excess amount of clay and silt in cement gives earthy cement.

Physical Properties of Cement

- Fineness of Cement

- The size of the particles of the cement is its fineness.

- It is an important factor to decide the rate of gain of strength and uniformity. In general, finer the grains higher the surface area.

- Test: Sieve Test

- Soundness of Cement

- Soundness refers to the ability of cement to not shrink upon hardening.

- Good quality cement retains its volume after setting without delayed expansion, which is caused by excessive free lime and magnesia.

- Test: Le Chatelier Test

- Consistency of Cement

- The ability of cement paste to flow is consistency.

- Test: Vicat Test

- Strength of Cement

- Three types of strength of cement are measured : compressive, tensile and flexural.

- Various factors affect the strength, such as water-cement ratio, cement-fine aggregate ratio, curing conditions, size and shape of a specimen, the manner of molding and mixing, loading conditions and age.

- Tests: AASHTO T 106, ASTM C 348

Typical Cement Fineness and Compressive Strength

- Setting Time of Cement

- Cement sets and hardens when water is added.

- This setting time can vary depending on multiple factors, such as fineness of cement, cement-water ratio, chemical content, and admixtures.

- Tests: AASHTO T 131 , ASTM C 191

- Heat of Hydration

- When water is added to cement, the reaction that takes place is called hydration.

- Hydration generates heat, which can affect the quality of the cement and also be beneficial in maintaining curing temperature during cold weather.

- Test: ASTM C 186

- Loss of Ignition

- Heating a cement sample at 900° - 1000° C (that is, until a constant weight is obtained) causes weight loss.

- This loss of weight upon heating is calculated as loss of ignition.

- Test: AASHTO T 105 , ASTM C 114

- Bulk density

- When cement is mixed with water, the water replaces areas where there would normally be air. Because of that, the bulk density of cement is not very important.

- The density of cement may be from 62-78 pounds per cubic foot.

- Specific Gravity (Relative Density)

- Specific gravity is generally used in mixture proportioning calculations.

- Test: AASHTO T 133, ASTM C 18

Chemical Properties of Cement

| Sr.No. | Ingredients | Percentage (%) |

| 1. | Alumina : Iron Oxide | > 0.66 |

| 2. | Lime: AluminaLime: IronOxideLime: Silica | > 0.66 or < 1.02 |

| 3. | Loss of Ignition | < 4 |

| 4. | Sulphur Content | < 2.75 |

| 5. | Weight of insolublere side | < 1.50 |

| 6. | Weight of magnesia reside | < 5 |

Common Applications of Cement

1. Construction

- It is used in mortar for plastering, masonry work, pointing, etc.

- It is used in concrete for laying floors, roofs and constructing lintels, beams, stairs, pillars etc.

2. Transport

- It is used in the construction of roads, pathways, crossings, bridges, tunnels, parking, sleepers, and runways etc

3. Hydrophilic Construction

- It is used in the construction of important engineering structures such as pipes, culverts, drains, canals, dams, weirs, reservoir, tanks and pools etc.

4. Miscellaneous

- It is used for constructing piers, docks, retaining wall and breast wall etc.

Types of Cement

| Sr.No. | Types of Cement | Reference Indian grades | Application |

|---|---|---|---|

| 1. | Ordinary Portland cement | Grade 33-IS: 269 Grade 43-IS: 8112 Grade 53-IS: 12269 |

|

| 2. | Portland Blast furnace Slag cement | IS:455 |

|

| 3. | Portland Pozzolana cement | IS:1489 |

|

| 4. | Rapid Hardening cement | IS:8041 |

|

| 5. | Extra Rapid Hardening cement |

|

|

| 6. | Acid Resistant cement |

|

|

| 7. | Sulphate resisting cement | IS:12330 |

|

| 8. | Low heat cement | IS:12600 |

|

| 9. | Hydrophobic cement | IS:8043 |

|

| 10. | Quick setting cement | - |

|

| 11. | Air entering cement | - |

|

| 12. | Masonry cement | IS:3466 |

|

| 13. | High alumina cement | IS:6452 |

|

| 14. | Expanding Cement | - |

|

| 15. | Oil well cement | IS:8229 |

|

| 16. | Coloured cement | - |

|

| 17. | White cement | IS:8042 |

|